Why Today’s Farm Machinery Demands Extra Protection

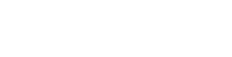

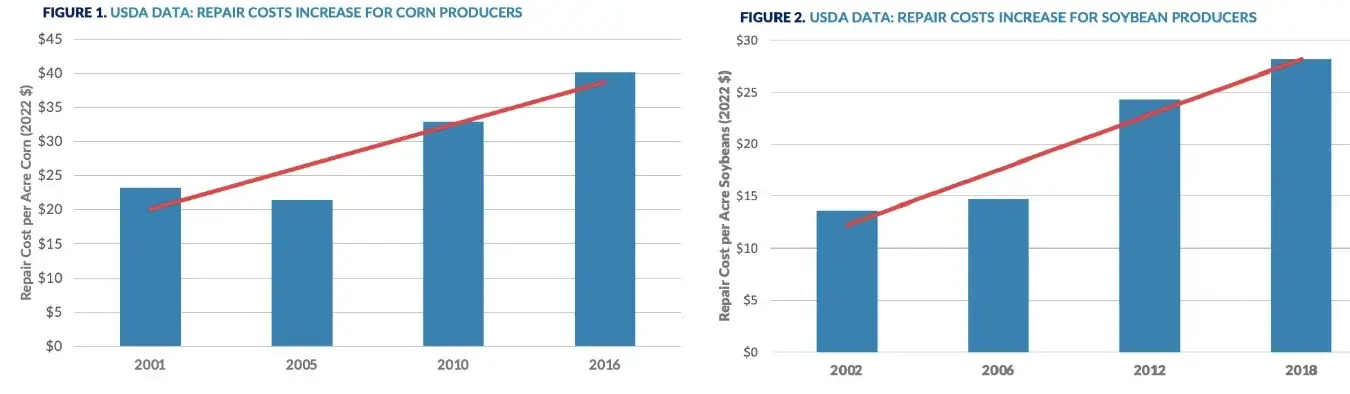

Modern farm equipment is costly to purchase and maintain. As a result, repair costs for agricultural machinery have nearly doubled over the past two decades, with a 41% increase since 2020. This rise is primarily due to higher parts and labor expenses. Additionally, the need for specialized repairs from dealers has increased because of technological advancements. Preventing costly overhauls with preventive maintenance has never been more important.

Figure 2 shows similar data for soybean producers between 2002 and 2018, with costs climbing from 15 per acre in 2002.

Public Interest Network. (2023). Out to Pasture: The Benefits of Letting Go of Factory Farms.

The Hidden Risk: Small Neglect Equals Big Bills

Seemingly minor issues like clogged radiators can escalate into major mechanical failures. Overheating isn’t just an inconvenience; it can lead to head gasket failures, turbocharger damage, or even complete engine overhauls. If you store your equipment outdoors, you may face even more significant risks due to debris buildup. As a result, dust accumulation increases, raising the likelihood of overheating and costly breakdowns.

The good news is that these problems are entirely preventable with regular maintenance. Simple checks can mean the difference between uninterrupted productivity and unexpected downtime.

Stay Ahead of the Problem with Preventative Maintenance

Protecting your equipment doesn’t have to be complicated. In fact, a proactive approach can prevent costly breakdowns and keep your machines running efficiently. To make the start of this season run a little more smoothly, we’ve put together a Pre-Season Checklist, helping you stay ahead of potential issues before they become expensive repairs. Print it, use it, and trust that Flexxaire has your back when it comes to maximizing your equipment’s performance and longevity.

Pre-Season Radiator & Cooling System Checklist

1. Radiator & Cooling Inspection

☐ Inspect thoroughly for any buildup and clean if required.

☐ Check coolant levels and top off or replace as needed

☐ Ensure the coolant mixture is correct for temperature conditions

☐ Look for radiator leaks; repair or replace damaged components

☐ Inspect radiator fins; straighten bent fins for optimal airflow

☐ Verify fan functionality; ensure it’s operating at full capacity

2. Fan System Maintenance

☐ Inspect fan blades for damage or wear

☐ Take a moment to test the reversing fan functionality (if applicable).

☐ Clear out dust and debris from fan housing

☐ Investigate the fan motor and connections

☐ It’s essential to check moving parts and lubricate them if necessary.

3. Hoses & Belts Check

☐ Inspect radiator hoses for cracks, bulges, or leaks

☐ Ensure hose clamps are tight and secure

☐ Examine belts for fraying, wear, or looseness

☐ Adjust or replace belts as necessary

4. Engine Compartment & Airflow

☐ Remove dirt and debris from around the radiator and engine

☐ Ensure proper shroud alignment for adequate airflow

☐ Verify that no obstructions are blocking the cooling system

Final Cooling System Check

☐ Perform a test run to monitor temperature levels

☐ Listen for unusual noises from the fan or radiator

Disclaimer: This checklist is for educational purposes only and should not replace the manufacturer’s guidelines. Always refer to the manufacturer for the most current information.

Flexxaire: Your Extra Layer of Protection Against Costly Breakdowns

Flexxaire’s reversing fan systems are a proactive solution to prevent overheating and maintain optimal engine performance.

How Flexxaire Safeguards Your Investment

- Self-Cleaning Technology: The reversing fan design automatically ejects debris, reducing the risk of radiator clogs and associated overheating.

- Fuel Efficiency: By maintaining proper engine temperatures, Flexxaire fans help reduce engine strain, improving fuel efficiency.

- Extended Engine Life: Consistent cooling minimizes thermal stress on engine components, potentially prolonging the lifespan of your machinery.

Why Farmers Choose Flexxaire

- Proven Performance: Designed to withstand challenging conditions, Flexxaire fans are trusted by farmers to keep equipment running smoothly.

- Brand Compatibility: Flexxaire systems are compatible with major equipment brands, ensuring seamless integration into your existing machinery. Use our Fan Finder to check out the fan custom designed for your machine.

- Independence: Flexxaire systems allow for more straightforward fan installation, maintenance, and repairs.

- Cost-Effective: Investing in a Flexxaire Fan can lead to savings by reducing downtime and maintenance expenses.

Find the Perfect Fit

Let us help you find the best Flexxaire solution for your equipment. Contact us now, and we’ll connect you with a dealer near you!