Energreen and Flexxaire: The Engine That Breathes!

ENERGREEN‘s professional brush cutting machines, thanks to their innovative technological content, excellent performance, operational flexibility and safety at work, represent a cutting-edge European product in the green maintenance sector.

Energreen boasts a fleet of five different models of remote-controlled multi-purpose tool carries with engines ranging from 33 hp to 173 hp and can operate safely with sophisticated remote control systems up to 55° gradients. These machines are designed to work in areas that are difficult for traditional machines; such as slopes along roads, motorways, embankments and difficult to reach or marshy areas particularly in the forestry industry.

Energreen has been on the market since 2010 with the RoboGREEN, specialized in a demanding and emerging sector. RoboGREEN is a remote-controlled multi-purpose tool carrier that can work in the most hostile places, with slopes up to 55° and where the access is very difficult. It is powered by a 40 hp diesel engine can be equipped with multiple attachments. Its reliability, robustness, and performance differentiate it completely from any other remote-controlled machine. The “bigger brother” has been called RoboMAX, powered by an 80 hp engine, it is a multi-purpose tool holder that skillfully lends itself to a variety of industries and activities.

In parallel to radio-controlled equipment carriers, Energreen also produces five models of self-propelled hydrostatic machines that can be equipped with telescopic arms with a length range from 6 up to 17 meters.

The ILF S1500, for example, is a machine designed to work on roads, motorways and canal embankments in conditions of maximum productivity and safety. The 17-meter-long boom of the ILF B2000, with its gritty 6-cylinder 220 hp engine, allows 360° working conditions thanks to its turret structure, a classic system used by hydraulic excavators, but with premium technologies.

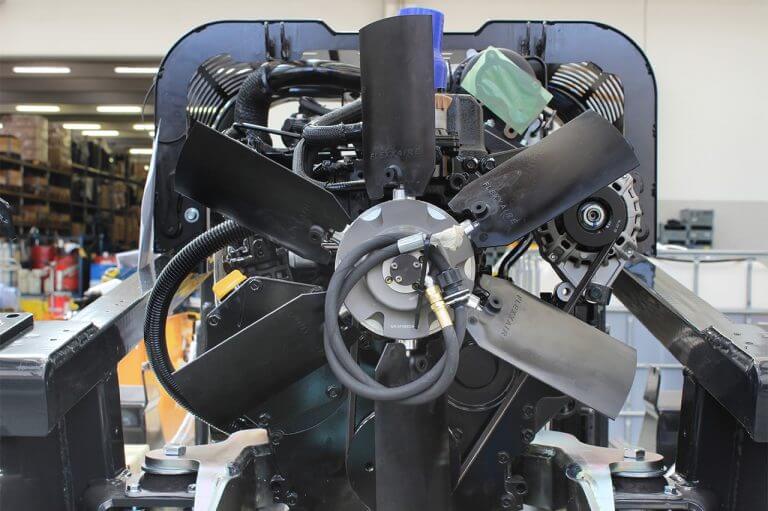

All the products produced by Energreen are designed to work in dusty and dirty environments, so RoboGREEN, RoboGREEN, RoboMAX, ILF S1500, ILF B2000 and ILF C1200 are equipped with the reversible hydraulic fan provided by Flexxaire to keep the performance of the engine and hydraulic systems constant at the maximum efficiency. This system blows away residues that block cooling radiator grilles, improve engine efficiency and optimizes cooling air flow thanks to the fan’s ability to reduce power consumption when maximum airflow is not required. This results in fuel savings, optimum engine temperatures, noise reduction and improved overall machine efficiency.

Flexxaire has been involved from the earliest stages of the projects, and technicians from both companies worked closely together to optimize the machines. The performances of the Flexxaire Fan are a benchmark in the reversible fan market and Flexxaire’s ability to perform numerical fluid dynamics analysis (CFD), a state-of-the-art wind tunnel and proprietary performance simulation software make Flexxaire the ideal partner for the engine cooling management.