Flexxaire reversible fans help TANA machines perform at their highest

Tana Oy is a privately owned Finnish company founded in 1971. Ever since then, the company has manufactured high-quality machines for solid waste treatment. Its product range includes shredders, compactors, and screens for demanding industrial applications. All TANA products aim at providing customers with maximum efficiency and profit – even in dusty conditions. Flexxaire fan products are the perfect choice for TANA machines, as they support that goal.

Tana Oy manufactures robust machines for diverse waste management processes. TANA Shark shredders are used in waste recycling to enable the separation of valuable materials from different wastes, to reduce volume and to generate a homogeneous particle size. TANA landfill compactors are the first purpose-built compactors in the world. They are used in reducing the volume of the waste in landfills and thus prolonging the landfills’ lifecycle. TANA screens are used to produce cleaner and purer material flows. They enable the recovery and recycling of valuable materials as well as the processing of waste into fuel.

Tana aims for maximum efficiency – even in dusty conditions

TANA machines operate in challenging conditions and process even the toughest of wastes. Operating environments, such as landfills and waste management facilities, are often very dusty. Moreover, the materials and their processing generate dust. Any component or sub-assembly that cannot handle these extreme conditions compromise the machine’s performance.

TANA products aim at providing operators in the waste management sector maximum efficiency and profit. This means that all the machines and every single component in them need to deliver maximum performance, minimum downtime and optimal operations.

Flexxaire reversible fans guarantee optimal performance and minimum downtime

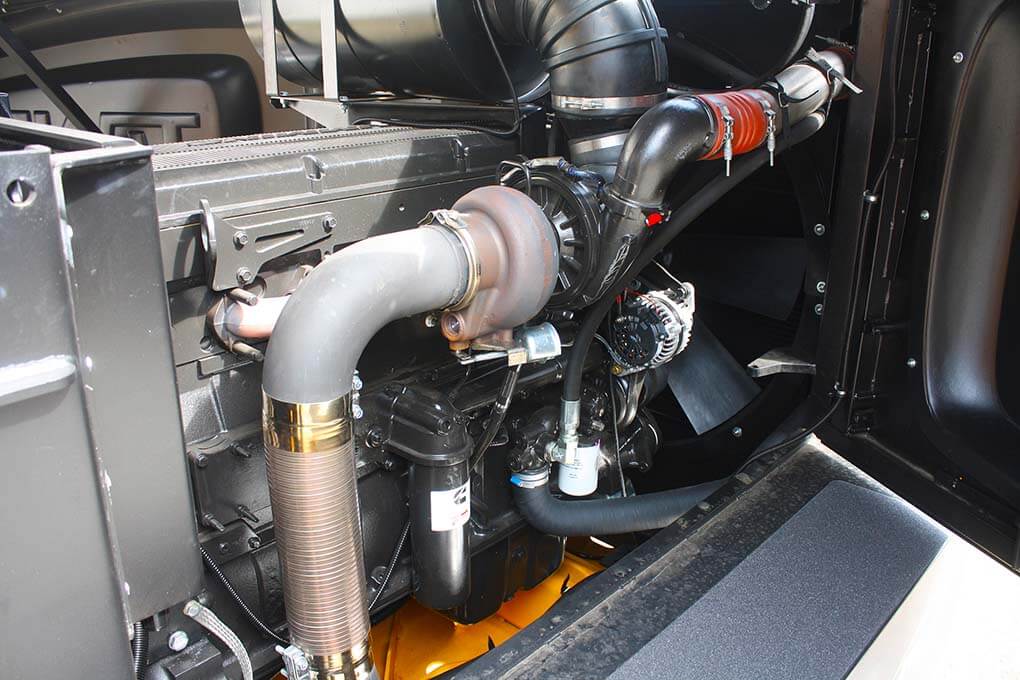

Flexxaire’s fan system helps reduce downtime and deliver maximum performance. Machine automation controls the fan’s cleaning cycles, minimizing manual clean-ups during work shifts. This is extremely important in the dusty conditions TANA machines operate in.

An automation system controls the fan according to temperatures, which minimizes fuel consumption and dust build-up. This creates savings in fuel costs. Alternatively, the saved energy can be converted into increased net engine power. This makes the system highly efficient. The construction is also robust, making it a strong link in the assembly.

All these features of the Flexxaire fan system make it a perfect fit for TANA machines, as they support Tana’s main objective of providing their customers with maximum efficiency and minimum downtime.